#how to use FDM printer

Explore tagged Tumblr posts

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing#3D printing maintenance

1 note

·

View note

Text

Since this response got out of hand, I'm giving it its' own post.

It's dangerous to ask a maker (artist?) about their processes @lonewolflupe @ulchabhangorm. But since you're curious, please accept my very first:

All of the pictured things were 3D printed by me on my FDM printer (Bambu Labs A1), including the teeny helmets. The non-helmet bits are pieces of Tech's armour. I'm currently building a Tech kit for 501st Legion approval. I "like" Crosshair and Scorch the most, but I am "most like" Tech. /sigh

I do! (Mostly) All of the armour parts of Archers' kit were 3D printed and finished by me on my FDM printer, with the exception of my pauldrons which were resin printed by someone else, but finished by me. I initially began making the kit for a Halloween costume, challenged by a coworker to a work-Halloween costume contest, but ended up meeting a couple vode from the Mando Mercs club (MMCC). I was invited (gently coerced?) to complete the kit to their standards and join the club. I'm in that process now, but still have a few things to finish before I gain Official Member status. 🙂

I made a lil' Boba candy bucket!!

3. I mostly print with PLA+. I can print with PETG, ABS, and other materials but my printer is running inside a spare room and I'm not set up with an enclosure or awesome ventilation yet to print with materials which off gas more toxic VOCs. Although PETG would be stronger for a buy'ce that is going to be worn PLA+ works just fine for most folks who are not in very hot conditions. (PLA will sag and melt in high heat) . The first time I wore my full kit, I was at work, and did a full day of fieldwork in it. The whole kit survived apart from one of the thrusters on my jetpack which I accidentally busted off while putting it back in the kit box (adhesive failure, I should have used hardware but I was in a rush to finish it before Halloween) . All fixed now! PLA would be just fine for printing teeny and/or decorative helmets. Just don't toss full size ones onto the floor off of a shelf (ask me how I know).

4. You can get STLs for clone helmets in all the places you'd expect (cults, thingiverse, etc) and from vendors on Etsy. Be careful, though, some of those files are stolen, and some are REALLY terrible and inaccurate. I usually avoid 'free' files, as for things as complex as helmets often end up being more costly in other ways, or are just not the quality I want. Galactic Armory has a nice selection of clone helmets (I have..... all of them. /embarrassment). Marko of Mystery Makers has really great Bad Batch (and other SW) helmets. He always tries to go a step beyond other modelers with his designs, both with functionality and accuracy. The Crosshair and RC helmet in my original post are both printed from Mystery Makers files. The RC helmet is the closest to the game design available, and the Cross helmet has a super cool functional rangefinder (like the different lenses are there and flip up and down, not just the whole rangefinder stalk moving). The Tech helmet is printed from Galactic Armory files, as are the rest (with the exception of Archers helmet which is AlterEgo, if I recall). The teeny helmets are printed from the full size files, just scaled down to 25%. I wouldn't' try to print these on an SLA/LCD resin printer, because the supports would be a nightmare I think, but it works just fine on an FDM printer. The most difficult part is printing the teeny greeblies for them which are super teeny at 25%. I almost always end up breaking the lil' rangefinder stalks, and am pretty sure I've lost the tusks for Rex's helmet more than once.

Cross WIP (Mystery Makers) with teeny (30%) Cross (Galactic Armory) 💙 Guess how many times I broke that teeny rangefinder stalk? Yeah. Four. 😖

Likewise, guess how many times I broke and lost the SUPER TEENY antennae on Tiny Tech's helmet? 😫

5. The visors in the full size helmets are generally welding/grinding replacement shields (Hobart brand, usually - available on Amazon). They are dark enough to obscure the wearers face and can be fairly easily cut to shape and installed. Tech's visor and goggle lenses are cut yellow acrylic, and in my original post still have the protective backing on them as they aren't 'officially' installed yet - which I why you can't see through them.

The visors for the full-size RC boys are more complicated. I believe the exact details of how I’ve been taught to do it are considered proprietary 🥺😏. To achieve the “Flirtation Mask” effect, two visors, a diffuser, and a strip of LEDs are installed in a very secret, not so secret, way. I’m working on a Scorch bucket, full size, and will have help to do this for the first time. Stay tuned. 😆 For the teeny helmets I use automotive window tint for the visors. It's easier to cut and bend into tiny shapes to fit inside the helmets. I got some blue stuff for the commando helmets, which should look cool once I install the lights. 😎

Teeny Gregor bucket WIP, with blue window tint FLIRTATION MASK 💙

6. The lil helmet stand under teeny Keeli (which I'm making for @eobe) is printed from a file from Galactic Armory. It's been through the ringer, because I use it to hold all the little helmets while I'm spray painting them and letting them cure. It did look nice when it was newer, and has the republic cog on the base. There is also a wall-mounted version which I have printed to hang Archer's helmet. I'll probably make more for the other helmets eventually.

7. VPLs (Visible Print Lines) are the enemy! As an MMCC member, it has been drilled into me that VPLs are evil and must be vanquished with extreme violence. I try to finish everything (with the exception of the flexi things people keep asking me to make) to an excellent standard with no VPLs - including the teeny helmets.

Raw Phase 1 (Animated) clone helmet and RC (Scorch) helmet). My printer does an excellent job, but still there are VPLs to be dealt with!

8. This question - how to get rid of VPLs could warrant it's own post. There are SO MANY techniques - some good, some NOT - but which ones you use depends largely on your print characteristics and what you intend to do with it. A lot of people lately have been recommending bathing the entire piece in a Bondo spot putty and acetone slurry several times until the lines are filled. I DO NOT recommend doing this for a piece that you intend to wear. I experimented with this and found out that after a small amount of wear the bondo likes to expel your paint in large chips, leaving ugly bondo-red spots behind. It would probably work ok for decorative pieces though. Other people have used UV curing resin to coat pieces to fill VPLs. It works, but UGH that stuff is toxic to touch and breathe, and it needs to be properly washed and cured, and cured some more. It's also much more difficult to sand than automotive body work products (which in all fairness are also toxic to breathe and touch - WEAR YOUR PPE).

My general process for armour pieces is to remove supports and then roughly sand (120 grit) only the really rough spots (like things that were overhangs or had a lot of supports). Sanding happens with a combination of sanding papers, sanding sticks, and needle files - depending on the piece. I then adhere pieces together (if they were printed in pieces like some of the larger full-size helmets) with plastic bonder. Seams are filled with Bondo plastic metal or EverCoat depending on the piece and I often plastic weld and staple the inside for strength. The seams are then sanded smooth. After I'm happy with the smoothness of the seams the entire piece will get 2-3 coats of automotive high-build filler primer (from a rattle can, though I have used the 1:4 mix stuff and brushed it on - I'd only recommend this with a large piece as that stuff REALLY fills things in quick - including the things you don't want it to) and a wet sand to 320 grit. At this point most of the print lines are filled, but stubborn areas, such as the top of the dome may still necessitate more coats. I generally end up applying 5 coats of filler primer, wet sanding between them. Following the final coat of filler primer, I'll wet sand again to about 400 grit (much more if we're going for the Beskar finish which needs a SUPER SMOOTH finish to work) and then put on a coat of regular primer. Black for helmets that will be dark (Most of the CF99 boys), and white for the other clone helmets. At this point they should be completely VPL free and ready for greebly installation and the "real" paint job. This process takes me at least a few days on full-size helmets as the paints have to cure between sanding and reapplication, and painting has to happen outside in good conditions. It's not inexpensive, but it is the most efficient and long-lasting way to do it, in my experience.

Cross helmet WIP. You can see the seam just under the visor cut out. This one printed in three pieces and needed ALL the seam filling and sanding. The pinkish and grey stuff are body fill products to fill in rough spots and seam lines. If you look at the last photo - of the same helmet - you can see they did a decent job of hiding that there was a seam. 😊

9. I use a lot of automotive products and paint. Since all my full size helmets are mean to be worn they need to be finished to a fairly high standard and be relatively tough. Archer's helmet body was finished entirely with Rustoleum brand filler primer and four layers of metallic paints (all rattle cans). The blue on the front was a Montana brand acrylic rattle can, and the copper parts (ear caps, rangefinder stalk) were enamel paint (Alclad copper) airbrushed on. The weathering - chips and scratches - were achieved by layering on a liquid latex medium between coats, so that when it was peeled off it revealed small bits of the coats beneath. It gives the damage a more realistic look than painting silver 'scratches' on after the fact. This liquid latex medium can be used to give the paint applied to clone helmets the chipped look to their painted designs as seen in the animation. It's a little more challenging to do in small scale though. After all the top coat paints are applied, I'll seal them in with a clear layer of satin or gloss sealant (rattle can). After that, I'll go over the entire piece with an acrylic black wash to make it look "dirty" and worn. 😅. After all that process, padding, visors, and electronics (HUD lights, fans, voice amps) are installed if needed. The whole thing is pretty time-consuming. I now understand why quality finished helmets cost as much as they do. My teeny helmets are all finished as I described above in the VPL section, but I use acrylics hand-painted on with a brush to apply the designs. In the animation versions of these helmets, particularly in TBB, the helmets all look like they've been (roughly) hand painted, so this technique works ok, I think. I apply the chipping and weathering at edges with dry brushing acrylics. I could apply a liquid latex mask and airbrush them, but eh. I'm using these little guys as fairy light "lanterns". They're super cute with the light showing a bit through the visors, particularly Tech. :)

The Teeny Batch boys that I've got finished. Echo is coming, he just needs his top coat and weathering. :D

Lil' Keeli almost finished, with his unfinished rangefinder. Have not broken the stalk yet! /cheer 🎉

10. Acrylics brand? Hmm... I've used the Montana Gold rattle can acrylics which some of the MMCC mandos seem to like. I'm not sure if the ones I got were duds, but I wasn't super impressed. The cans did a lot of spitting and messed up my paint a few times. My brush on acrylics are Liquitex or Golden. Both can be thinned and airbrushed, and are more costly than cheap crafting brands but are more highly pigmented and last longer (plus the finish is nicer).

11. Base colour is whatever primer I finish with - white or black, depending on what color the final piece will be. For Mando helmets, the base colour is a metallic silver, so that when I peel off the liquid latex layers, the pint chips down to “bare metal/beskar”. Since clone helmets are plastioid, the base colour for them remains white or black.

12. I finish with a rattle can sealant. Satin finish usually, but that depends on the look you want. Always try to stick with the same brand of primer, paint, and sealant. Different brands have different chemistry - accelerants and so on, and can, and often do react with one another. The frustration of having to sand down a piece that was almost finished cannot be described.

To avoid paint heartache, always also paint in good conditions. Temperature, humidity, wind, etc can all ruin you day and paint job. Please also always wear your PPE!

13. Are they? I hope they are. They sure are a labour of love, and much work - but it makes me happy to make them and to look at them. 😅

I'm very fond of Archer's buy'ce, and the whole kit really. It was the first one I 'finished' (every mando's kit is an ongoing WIP - forever), and the process of making it kept me focused on something positive during a rough time in my life. Wearing it is super fun! Ibic Manda!

WOW that got lengthy, so sorry! I had ALL the questions when I started, and a lot of the info you need is hard to find or in bits and pieces all over the internet. If you have any other questions, feel free to ask! I can only share my experience, but I have spent a huge amount of 2024 working on these for what that's worth. 🫣

#star wars#the bad batch#tbb crosshair#chaos squad#mandalorian oc#star wars oc#tbb#3d printing#tcw keeli#tcw gregor#tbb tech#tbb hunter#tbb wrecker#clone force 99#Archers Chaotic InfoDump Series

43 notes

·

View notes

Text

3Dprintum

Objectum attraction to 3d printers. Including, but not limited to, small, medium, large, plastic filaments printers (FDM/FFF), resin printers (SLA, DLP, MSLA). Yes, even concrete ones

The rainbow line represents ribbon cables/dupont jumper wires that sometimes are exposed, especially on FDM printers, or plastic/resin/other material that it works with. Depends on how you want to see it.

The darker lines are the layers of filament, because FDM printers print in layers, from top to bottom.

And stringing (the light strings that can be visible on almost white line).

Oversimplified explanation of what stringing is👇

What is stringing? Imagine using a hot glue gun to draw lines on paper. If you move the glue gun from one spot to another without stopping the flow, thin strands of glue will stretch between the two points. In 3D printing, the printer’s nozzle melts and extrudes plastic, and if it doesn’t stop properly when moving between different areas, it can leave behind thin, unwanted plastic strands—this is called stringing.

#objectum#techum#3Dprintum#printer#printer objectum#3d printer objectum#3d printer#flag coining#flag making#objectum flag#objectum coining#has id

18 notes

·

View notes

Text

An Aurora Borealis is Localized Entirely Within my Hobby Desk!

Shortly after getting my first 3D printer this past November (a Bambu Lab P1S), I knew that I wanted to print a mech scale DropShip. Considering that I love the HBS Battletech PC game, I wanted it to be a Leopard dropship, but I couldn't find one that was in proper mech scale that was simple to print and based on that version of the Leopard. Then I found the Borealis print from Thunderhead Studios. This is based on the Aurora dropship, and i LOVE this thing. it prints in FDM BEAUTIFULLY and the fact that the drop pods can hold units in them tends to delight and surprise everyone who takes notice (and who wouldn't in that beautiful Sword of Light red!)

Painting this beauty took me about a month because I wanted to take my time with her. Also, she is my first concerted effort to really weather a model using the techniques I learned from a 1:1 tutoring session from local artist Devin Bush who's weathering game is absolutely top freaking notch.

I am most proud of the corrosion on the central pipes along the spine of the borealis and the battle damaged fin (the final image in the gallery). The latter was a build/print error I didn't notice until well into painting the model. I decided to play it off as a significant piece of battle damage that the crew hasn't had a chance to fix yet. Thank Blake that we always have that convenient excuse to cover up build/print errors!

Overall, I am over the moon with how she came out. Now to make up some excuses to put her into a game...

#battletech#alpha strike#hextech#thunderhead#painting miniatures#miniature#hobby#mini painting#wargaming#minatures#weathering#happy accidents

17 notes

·

View notes

Text

It's now been a year since my sister passed away. This past week Camp About Face held a... Melmorial for her down at Bradford Woods in Indiana.

More after the break but I think I've gotten closure since then. That and I think for the next few years I'm going to paint up a full Star in her honor. I finished the Hammerhead last year and this year, a Stormcrow TC/K. We'll see how things go from here.

So it has been one year to the day now that we held her funeral. I suppose it's true what they say. There'll always be a hole where someone leaves when they're gone but in time you'll grow around it. There will always be that random instant where you get slammed full force with and emotional brick of sorrow but in time you learn to at least move with the blow instead of against it. I won't have as much as much to write down this time around.

Riley's Children Hospital and Camp About Face decided to commemorate my sisters time here with a park bench. We haven't quite hammered down where it will end up there but we're leaning towards the Memory Garden.

She was very fond of this place. Not just the Memory Garden but the whole camp. I felt a peace there I hadn't felt in a while.

I'm glad I finally got down there to see it. It was always just kind of Mel's space for years. Apparently while things were starting to go bad during the end she would relate to my Father about her times there, the switchback trails, and the woods. I feel it matched up with what she told him. I'll miss her.

As strange as a tribute as this sounds, I have decided to paint up a Star of Mechs in the colors she chose for the Hammerhead.

Probably a bit weird, a bit touched in the head but hey, it's how my strange little mind works.

So I chose a Stormcrow TC/K for her second Mech. Specifically the Premium version from Catalyst. This particular release has had a bit of infamy as they somehow managed to invert the arms, turn it into a southpaw. This works nicely for me as my sister was left handed. Seems fitting.

I'm particularly proud on how it turned out. I used almost the same paints as last time of course, along with my usual fixation on glow in the dark pop. Although the basing is somewhat of a flourish. Earlier this year we went down to San Diego to visit family and the beach where we scattered some her cremains to the Pacific. So yeah I took some of the sand from the beach and used it as basing for the hex, along with a tuft of tundra grass from green stuff world and a bit of glow in the dark support from a FDM 3D printer. I have also took sond sand from the beach in Bradford Woods to use for the next Mech in the Star. Anyone know of some other southpaw Mechs?

Going from morbid to slightly less morbid, or at least a different kind of morbid. I know I'll never forget my sister and will always have her in the back of my head but she wouldn't want me to dwell on her passing any long than I have to. To quote her exactly, "Get over it". She'd also roll her eyes in the way only she could do. So I will endeavor to continue onward.

We have started going through some her personal odds, ends, journals, and recordings from over the years so I'll leave you all with a note she got from a friend on her birthday a few years back.

P.S.- here's a direct link to when she first passed away and me completing her Hammerhead.

30 notes

·

View notes

Text

My friend commissioned a dice tower that requires the use of my resin printer, which I haven't booted up in over a year now. I panicked, thinking if it broke or something. When I turned it on, and decided to start printing, well... the z axis ceased moving entirely. And that's when the REAL fear set in.

Until I recognized I simply had to turn off the printer, and turn it on again.

How dumb of me. The most complex things require the simplest solutions sometimes...

Well! Time for a really REALLY cool dice tower!!

I'm printing the tower itself in FDM using the Anycubic Chiron, and the guardians on either side with resin, using the Anycubic Photon Zero. Yes, I still have that printer. Yes, it works like a gem. Yes, it's tiny as fuck, and I want an upgrade DESPERATELY!!!!

73 notes

·

View notes

Text

Hi y'all!

I'm always down for asks! Though I make no promises to have all the answers. I'm pretty sociable so feel free to interact!

I don't really intend to frequently post NSFW, but if I do, I'll always community tag cover it. Please see Tags of Note below for more details on what you may want to mute..

I've also got an alt where I do most of my reblogs so this page can stay clean: @civilotterneerredlines

I've also got a Bluesky that I mainly just repost some of my art on: @civilotterneer.bsky.social

I am doing my best to keep my FurAffinity account updated, but it's also the main place I'll store Not-Safe-For-Tumblr art:

https://www.furaffinity.net/user/civilotterneer/

Master list of my larger projects can be found at the end of this blurb.

Wanna know more?

Master List:

Laundry Day - Funny lewd comic about CIv doing laundry

The Search for Civ - Civ has gone missing, how will Lye find him?

Civ Plays: Baldur's Gate 3

Tags of Note:

#Civil Otterneer - I use this to tag all posts I make.

#uncivilotterneer - horny posting, and NSFW. This blanket terms all directly lewd posts, but may not catch stuff considered only 'spicy' as per the speedo tag below.

#speedo - posts where characters are shirtless or wearing very little, like a Speedo, typically not with sexual intent, but stuff may be a bit spicy.

#Civ or #Civ OC: Civ - Civ! My main fursona and primary character

#Lye or #Civ OC: Lye- Civ's friend and housemate, a cat necromancer (The Nekomancer, lol)

#Livic or #Civ OC: Livic - Civ's devilish copy and roommate, a devilish otter

#Civ OC: Xaphar: Xaph - Civ's old friend and romantic interest, a blue dragon

#The Otterneer-verse: Lore and malarkey about the world Civ and his friends live in

#The Reality Room - comics involving Civ and a magical virtual reality device

#ask - posts with asks from people

Fun facts:

I am a practicing civil engineer-in-training. I originally got a degree in environmental engineering, but civil speaks to me more now (they're very similar degrees so it's in fact possible to switch post-college). I'm focusing my work in wastewater and water treatment, with a healthy amount of site grading and water/sewer pipe networks for the city.

I swim just about every day I can, which is pretty close to daily. Thus my fursona's an otter to reflect that. Plus I'm just a silly little guy sometimes.

Ich lerne Deutsch, aber Ich bin nicht sehr gut.

I enjoy tabletop games a ton. Big fan of DND/Starfinder and I'm currently running a Starfinder campaign. I also play a bit of MTG, but more often I play Star Wars Armada, which I paint and homebrew for.

I have 2 3D printers, one FDM and one Resin. I'm typically printing game pieces for Armada, which a roommate and I are currently using to make a Star Trek, UNSC, and Covenant faction for the game. I also 3D print mini's for DND, and my roommate group paints them. The FDM is the favorite child, though its older so maybe that's unfair. (I'd like to note that she's now in her rebellious stage and tends to malfunction more now. The resin's now the grade A student)

I've got two pets: one's my mutt Lady (she's a rez mutt with mixed aussie, german shep, sheep dog, herder, and about every other breed on the rez), the other's my snake Striker (lesser morph ball python).

Base model originally by https://x.com/GalileoGB?t=A570ht3M6JPpeOog-Rn3Kg&s=09

49 notes

·

View notes

Text

How to Paint a Beholder*: Tips and Tricks

11/29/2024 My latest video on painting an Angry Ball of Eyes from Fat Dragon Games is now live on YouTube. I really like this model and have done this a dozen times. The image above is a model I painted a couple of years ago. I use this for the mascot for my Etsy store (DMDavidsPrints). It is a fun model that can be printed supportless on a FDM printer so anyone with any style 3D printer can…

2 notes

·

View notes

Text

3rd party resin print tomb kings horse archers vs. the official gw plastic models.

I'm not a fan of the official gw tomb kings skeleton cavalry. They have a goofy toyetic charm that isn't entirely lost on my, and they were certainly good enough for their time, but that time passed long ago. So when my planned horse archer conversion using black knight bits didn't pan out, I broke down and tried resin 3d printed models, ordered from an online shop since my small apartment doesn't have the space to deal with resin safely.

So on the left are 10 3rd party horse archers - 'Second Dynasty Knights' designed by Lost Kingdom, ordered from online printing house Coveted Forge, with a special request to replace spears & shields with more bows & quivers.

The designs by Lost Kingdom are fantastic, much better proportioned, very dynamic, and the large sideways quivers give the riders a distinct silhouette. I will say the skinny bones, bows, and arrows feel super fragile though, and its not always entirely clear how or which hooves are supposed to glue to the base.

The prints from coveted forge took about a month to arrive, and came packaged super well. There was one quiver missing, which they're re-sending. I've been very happy with fdm printed bases & unit trays from Coveted Forge, this is my first time ordering resin prints. The pieces had no misprints and were cleaned cleaned with just a few leftover supports or studs to trim from where supports were removed, & everything was intact despite how fragile it all is. The scale was a bit larger than advertised - i purchased '28mm' scale, but the skeleton riders are about 34mm tall. The size is still fine for what I'm using them for, so it's fine. I've come to expect minis will usually be a bit larger scale than advertized, plus the pieces came in parts so the actual scale wouldn't have been obvious when printing.

Unfortunately, I'm just not a fan of resin as a material. Details are a bit soft, and the material feels both softer and less fragile, which is more an issue for skinny skeletons than most other stuff. Different printers or different resin might give a better result, but fundamentally I just don't think resin printing will ever be on the same level as GW's modern injection molded plastic.

I don't think I want to make resin prints a regular part of my minis collection, but in this case I like the sculpts ~so much~ better than the official models that I'm willing to deal with it, even if I have to keep backups of the official models anyway in case i ever play Old World at a GW store or event.

2 notes

·

View notes

Text

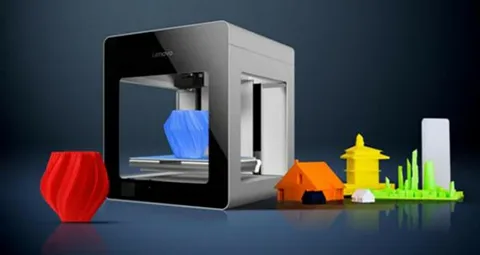

Discover How 3D Print Services and Cheap 3D Printer India Solutions Are Transforming Innovation

In recent years, 3D printing technology has emerged as a powerful tool across industries—from prototyping and manufacturing to healthcare and education. Businesses and individuals alike are reaping the benefits of rapid, cost-effective production using modern 3D printers. With increasing accessibility, more Indians are turning to 3D print services and exploring options for a cheap 3D printer in India to bring their ideas to life.

Why 3D Printing Is Gaining Momentum

3D printing, also known as additive manufacturing, creates physical objects by layering material based on a digital model. This process dramatically reduces waste, speeds up prototyping, and allows for the customization of products that traditional manufacturing struggles to offer.

Designers, architects, engineers, hobbyists, and students are now using 3D printing for projects ranging from miniatures and machine parts to architectural models and medical implants. The rising interest has spurred the growth of reliable and affordable 3D print services and a market boom for cheap 3D printer India options.

What Are 3D Print Services?

3D print services allow you to print a design without owning a 3D printer yourself. You simply upload your CAD file to an online portal or visit a local 3D printing center, choose your preferred material, and let experts do the rest. These services are ideal for those who need professional prints occasionally or want high-quality output without investing in expensive machines.

In India, the demand for professional 3D printing has surged across metro cities like Bangalore, Delhi, Mumbai, and Hyderabad. Companies offer services like rapid prototyping, industrial modeling, product design, and even small-batch production. Whether you're a student working on a science fair project or a startup developing a new prototype, 3D print services provide flexible, on-demand solutions.

Exploring the Market for a Cheap 3D Printer in India

While outsourcing printing to professional services is convenient, many hobbyists and startups prefer owning a machine for hands-on experience and long-term savings. The good news is that the Indian market offers a wide range of options for those seeking a cheap 3D printer in India without compromising on performance.

Entry-level FDM (Fused Deposition Modeling) printers are now available at affordable prices, starting as low as ₹15,000 to ₹30,000. Brands like Creality, Anycubic, Wanhao, and Indian-made Pramaan 3D have released budget-friendly models that cater to both beginners and advanced users.

These machines support common filament types like PLA, ABS, and PETG, and some even come with open-source firmware for customization. With online tutorials and active user communities, it’s easier than ever to set up and operate a cheap 3D printer in India from your home or workshop.

Benefits of Using 3D Print Services and Owning a Cheap 3D Printer

Both 3D print services and affordable personal printers offer distinct benefits, depending on your needs:

Advantages of 3D Print Services:

Professional Quality: Get access to high-resolution industrial-grade printers.

Variety of Materials: Choose from advanced resins, metals, and composites.

No Maintenance Hassle: Avoid the setup, calibration, and upkeep involved in running your own printer.

Expert Guidance: Collaborate with technicians who can help optimize your design for the best results.

Advantages of Cheap 3D Printers in India:

Affordability: Entry-level printers are budget-friendly and easily available online and offline.

Learning Opportunity: Great for students and makers to understand the nuances of 3D modeling and printing.

Creative Control: Make quick iterations and modifications in real time without relying on a third party.

Business Potential: Entrepreneurs can start small-scale manufacturing or offer local 3D print services in their area.

Who Can Benefit from 3D Printing?

The applications of 3D printing extend far beyond engineering and manufacturing. Here’s a look at some key users:

Students and Educators: Ideal for STEM education, science models, and project-based learning.

Architects: Use 3D printing for scale models, elevation designs, and visual presentations.

Healthcare Professionals: Print prosthetics, surgical tools, and anatomical models.

Artists and Designers: Bring creative ideas to life with customized jewelry, home decor, and wearable tech.

Entrepreneurs: Launch product-based businesses with minimal initial investment using a cheap 3D printer India setup.

Final Thoughts: Embrace the Future with 3D Printing

The 3D printing landscape in India is rapidly evolving. As awareness grows, both 3D print services and affordable home-use machines are making innovation more accessible than ever. Whether you want to prototype a new invention, create personalized items, or enter the world of digital manufacturing, now is the perfect time to explore your options.

Investing in a cheap 3D printer in India or partnering with a local 3D print service can unlock endless possibilities for your creativity or business. As technology continues to advance, those who adopt 3D printing today will lead the way in shaping the products and solutions of tomorrow.

0 notes

Text

#FDM 3D printer setup#Fused Deposition Modeling#3D printing guide#how to use FDM printer#3D printer calibration#filament loading#troubleshooting 3D printing issues#FDM printing materials#3D printing tips#PrusaSlicer#Cura#3D model slicing

1 note

·

View note

Text

Desktop 3D Printer Market Growth Drivers Transforming Additive Manufacturing Industry Globally

The desktop 3D printer market has witnessed remarkable growth over recent years, revolutionizing how products are designed, prototyped, and even manufactured. As additive manufacturing technology continues to advance, the demand for desktop-sized 3D printers has surged among hobbyists, educators, small businesses, and professionals. Understanding the primary drivers behind this market growth is essential for stakeholders aiming to capitalize on the expanding opportunities. This article delves into the key factors propelling the desktop 3D printer market forward.

1. Technological Advancements and Innovation

One of the most significant drivers behind the desktop 3D printer market is ongoing technological innovation. Improvements in printer hardware, including better precision, faster print speeds, and enhanced reliability, have made desktop 3D printers more accessible and capable. The evolution from basic fused deposition modeling (FDM) to more sophisticated technologies such as stereolithography (SLA) and digital light processing (DLP) has broadened application possibilities, encouraging more users to adopt desktop 3D printing.

Moreover, advances in printing materials—from plastics to composites and even metal-infused filaments—have expanded the functional range of desktop 3D printers. These improvements enable users to create durable, high-quality prototypes and end-use parts, making desktop 3D printing a viable option across many industries.

2. Decreasing Costs and Increasing Affordability

Cost reduction is another powerful driver for the desktop 3D printer market. Early 3D printers were prohibitively expensive for individual users and small businesses. However, economies of scale, increased competition among manufacturers, and technological maturity have drastically lowered prices. Today, entry-level desktop 3D printers are available at affordable prices, opening the market to hobbyists, students, and startups.

Alongside hardware costs, the decreasing price of printing materials and software solutions further contributes to affordability. This overall reduction in total cost of ownership encourages wider adoption and frequent usage of desktop 3D printers.

3. Growing Demand for Rapid Prototyping and Customization

Industries increasingly demand rapid prototyping to accelerate product development cycles. Desktop 3D printers allow designers and engineers to quickly iterate designs without relying on costly third-party manufacturing. This on-demand prototyping significantly reduces lead times, lowers development costs, and enables faster time-to-market.

Additionally, the rise of mass customization in sectors like healthcare, fashion, and consumer goods boosts the need for flexible manufacturing solutions. Desktop 3D printers empower small-scale production of customized items tailored to individual specifications, meeting customer demands for uniqueness and personalization.

4. Expansion of Educational and DIY Markets

Educational institutions and maker communities play an influential role in expanding the desktop 3D printer market. Schools and universities integrate 3D printing into STEM curricula to provide students hands-on experience with emerging technologies. This exposure cultivates future professionals familiar with additive manufacturing, thereby sustaining market growth.

The DIY and maker movement thrives on accessible, affordable desktop 3D printers, enabling enthusiasts to create prototypes, replacement parts, and artistic projects. Online communities sharing designs and knowledge stimulate further interest and innovation, broadening the user base.

5. Enhanced Software and User-Friendly Interfaces

User experience improvements drive the market by making 3D printing less intimidating for new users. Advanced software with intuitive interfaces, pre-configured print profiles, and automated calibration simplify the printing process. Cloud-based platforms and mobile apps offer seamless remote management, design sharing, and collaboration.

Such user-friendly solutions lower the entry barriers and increase productivity, encouraging adoption by non-technical users and businesses alike.

6. Increasing Adoption in Healthcare and Other Key Industries

The healthcare industry’s adoption of desktop 3D printing significantly influences market growth. Customized implants, surgical guides, prosthetics, and anatomical models are increasingly produced using desktop printers for personalized patient care. This sector’s expanding use cases highlight the practical benefits of desktop 3D printing technology.

Similarly, industries like automotive, aerospace, consumer electronics, and architecture are leveraging desktop 3D printers for prototyping, tooling, and small-batch production, driving broader market demand.

7. Government Initiatives and Investments

Government policies and initiatives promoting innovation and advanced manufacturing also act as growth drivers. Funding for research, subsidies for equipment acquisition, and support for technological education encourage adoption of desktop 3D printing. Such measures foster an ecosystem conducive to market expansion.

Conclusion

The desktop 3D printer market is propelled by a combination of technological innovations, cost reductions, and growing demand for rapid prototyping and customization. Expanding applications in education, healthcare, and industry further amplify growth prospects. As software becomes more user-friendly and governments support advanced manufacturing initiatives, the desktop 3D printer market is set to continue its dynamic growth trajectory, reshaping traditional manufacturing paradigms and enabling creativity across sectors.

0 notes

Text

Beginner’s Guide to 3D Printing: Everything You Need to Know

What is 3D Printing?

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. It builds objects layer by layer using materials like plastic, resin, or metal. Unlike traditional manufacturing that removes material, 3D printing adds it, allowing for complex, customized designs.

How Does 3D Printing Work?

The process starts with a 3D model, which can be designed using Computer-Aided Design (CAD) software or downloaded from online libraries like Thingiverse. This model is then sliced into thin horizontal layers using slicing software, generating G-code, the language your printer understands.

Once the printer receives the G-code, it begins printing the object one layer at a time. Depending on the material and method used, the printing time and quality can vary.

Types of 3D Printing Technologies

Here are the most common 3D printing technologies:

FDM (Fused Deposition Modeling) – Melts plastic filament layer by layer; cost-effective and ideal for prototypes.

SLA (Stereolithography) – Uses a laser to cure liquid resin; offers high detail and smooth finishes.

SLS (Selective Laser Sintering) – Uses a laser to fuse powdered materials; great for strong, functional parts.

Resin Printing – Delivers high-resolution results, often used for miniatures, jewelry, and dental models.

At Paradise 3D, we offer FDM, SLA, and Resin printing tailored to your project needs.

What Can You Print with 3D Printing?

The possibilities are nearly endless. Here are some popular applications:

Product prototypes

Custom phone holders

Architectural models

Engineering parts

Toys and figurines

Personalized gifts

Home decor

If you can imagine it, chances are we can print it!

Materials Used in 3D Printing

Different projects require different materials. Here are the most common ones:

PLA (Polylactic Acid): Easy to print, biodegradable, great for beginners

ABS: Durable and heat-resistant

PETG: Strong and flexible

Resin: High-detail and smooth finish

Nylon: Strong and wear-resistant

We help you choose the right material based on your design, purpose, and budget.

Getting Started with Paradise 3D

Ready to try 3D printing in Bangalore? Here's how to begin:

Design or find a 3D model

Send us your file via our website

Choose your material and finish

Get an instant quote

We print and deliver it to your doorstep!

Our expert team will guide you every step of the way, ensuring quality and satisfaction.

Why Choose Paradise 3D?

Local expertise with global standards

Affordable pricing and fast delivery

Advanced printing technologies (FDM, SLA, Resin)

Ideal for hobbyists, students, engineers, and entrepreneurs

Transparent and reliable service

We’re more than just a service; we’re your 3D printing partner in innovation.

Final Thoughts

3D printing is transforming how we create, design, and build. Whether you're a beginner experimenting with designs or a professional needing precise prototypes, Paradise 3D is here to bring your ideas to life.

Explore the future of making — right here in Bangalore.

Start your first 3D printing project today with Paradise 3D!

0 notes

Text

Custom Action Figure: The Ultimate Guide to Personalized Collectibles

Introduction

Custom action figures have become a popular trend among collectors, hobbyists, and fans of pop culture. Unlike mass-produced toys, these unique creations allow individuals to own one-of-a-kind figurines tailored to their preferences. Whether you want a custom action figure of yourself, a favorite character, or an original design, the possibilities are endless.

In this guide, we’ll explore the world of custom action figures, covering their creation process, popular customization options, and where to get them.

What Is a Custom Action Figure?

A custom action figure is a handcrafted or modified figurine designed to meet specific preferences. These can range from repainted existing figures to fully sculpted original pieces. Collectors and artists often create custom action figures to:

Represent themselves or loved ones in toy form

Bring fictional characters to life in unique ways

Fill gaps in official merchandise (e.g., unmade characters)

Showcase artistic skills through original designs

How Are Custom Action Figures Made?

Creating a custom action figure involves several techniques, depending on the desired outcome. Here’s a breakdown of the most common methods:

1. Repainting Existing Figures

Many custom action figures start with a base model, which is then repainted for a new look. This method is cost-effective and great for beginners.

Steps:

Disassemble the figure (if possible)

Sand down unwanted details

Apply primer for better paint adhesion

Hand-paint or airbrush new colors

Seal with a protective varnish

2. Kitbashing (Part Swapping)

Kitbashing involves combining parts from different figures to create a new design. This is popular for making unique characters or alternate versions of existing ones.

Example:

Using a superhero body with a different head sculpt

Mixing military gear with fantasy character parts

3. 3D Printing & Sculpting

For fully original designs, 3D modeling and printing allow complete customization. Artists can sculpt digital models and print them in resin or plastic.

Process:

Design the figure in 3D software (e.g., Blender, ZBrush)

Print in layers using a resin or FDM printer

Sand and paint for a polished finish

4. Clay & Hand-Sculpting

Traditional sculptors use materials like polymer clay (e.g., Sculpey) to handcraft custom action figures. This method requires skill but offers unmatched creativity.

Materials Needed:

Polymer clay or epoxy putty

Armature wire for structure

Sculpting tools for detailing

Popular Uses for Custom Action Figures

Custom action figures serve various purposes, from personal keepsakes to professional displays. Here are some of the most popular uses:

1. Personalized Gifts

A custom action figure modeled after a friend or family member makes a memorable gift for birthdays, weddings, or anniversaries.

2. Cosplay & Fan Art

Many fans create custom action figures of their cosplay designs or original characters (OCs) from games, comics, or anime.

3. Stop-Motion Animation

Independent filmmakers often use custom action figures for stop-motion projects, as they allow for unique character designs.

4. Collectible Art Pieces

Some artists sell limited-edition custom action figures as high-end collectibles, often displayed in art galleries or conventions.

Where to Buy or Commission Custom Action Figures

If you’re not into DIY, several artists and companies specialize in custom action figures. Here are some options:

1. Etsy & Online Marketplaces

Many independent artists sell custom action figures on Etsy, eBay, and Instagram. You can commission a personalized piece based on your preferences.

2. Professional Customizers

Some experienced customizers take commissions through social media or their websites. Look for artists with strong portfolios.

3. 3D Printing Services

Websites like Shapeways and Treatstock offer 3D printing services where you can upload a design and receive a physical figure.

4. Toy Customization Studios

Certain studios specialize in high-end custom action figures, often used for movie props or premium collectibles.

Tips for Creating Your Own Custom Action Figure

If you want to try making a custom action figure, here are some helpful tips:

Start Simple: Begin with repaints or minor modifications before attempting full sculpts.

Use Quality Materials: Invest in good paints (e.g., Citadel, Vallejo) and sculpting tools.

Study Anatomy: Understanding proportions will improve your designs.

Practice Detailing: Small touches like weathering or shading add realism.

Join Communities: Forums like /r/ArticulatedPlastic (Reddit) offer advice and inspiration.

Conclusion

Custom action figures offer a creative way to express fandom, artistry, and personalization. Whether you buy from an artist or make your own, these unique collectibles bring imagination to life. With the right tools and techniques, anyone can dive into the world of custom action figures and create something truly special.

Would you rather commission a custom action figure or try making one yourself? The choice is yours—happy customizing!

1 note

·

View note

Text

Expert 3D Printing in Riyadh | Advanced Additive Manufacturing

In today’s fast-paced world, innovation drives success — and 3D printing is at the heart of this revolution. At 3DWorksMe, we bring cutting-edge 3D printing services in Riyadh, helping businesses and individuals transform ideas into reality with precision and speed. Whether you need rapid prototyping, custom manufacturing, or complex industrial solutions, we are your trusted partner for advanced additive manufacturing in Riyadh.

Why Choose 3DWorksMe for 3D Printing in Riyadh?

State-of-the-Art Technology: We use the latest 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). This allows us to produce high-quality prototypes, intricate models, and end-use products with exceptional accuracy.

Customized Solutions: Every project is unique, and so are our solutions. Whether you're in the medical, automotive, architectural, or industrial sector, we tailor our 3D printing services to meet your specific needs.

Fast Turnaround Times: Time is money. Our rapid prototyping services ensure you get your 3D-printed parts quickly, enabling faster design iterations and product launches.

Cost-Effective Manufacturing: 3D printing reduces waste by using only the material needed to create your product. This cost-efficient process makes high-quality production more affordable for businesses in Riyadh.

Applications of 3D Printing in Riyadh

1. Prototyping and Product Development: Bring your ideas to life with accurate, functional prototypes. Our 3D printing technology allows you to test and refine your designs before committing to full-scale production.

2. Architectural Models: Showcase your building designs with intricate, high-resolution 3D models. Architects and real estate developers in Riyadh use our services to present their projects with clarity and precision.

3. Medical and Healthcare: From custom prosthetics to dental implants, 3D printing is revolutionizing the healthcare sector in Riyadh. We create tailored solutions for medical professionals and researchers.

4. Industrial Manufacturing: Produce complex parts and custom tools with ease. Our industrial-grade 3D printers help manufacturers in Riyadh streamline their production processes.

5. Custom End-Use Products: Need personalized or low-volume parts? 3DWorksMe delivers durable and functional end-use products tailored to your specifications.

Partner with the Best 3D Printing Company in Riyadh

At 3DWorksMe, we combine technology, expertise, and creativity to offer the best 3D printing solutions in Riyadh. Our team works closely with you to understand your requirements and deliver products that exceed expectations.

Ready to embrace the future of manufacturing? Contact 3DWorksMe today to learn more about how our advanced 3D printing services in Riyadh can drive innovation for your business.

Let’s build the future — one layer at a time!

0 notes

Note

Hi, I love your 3d prints!! May I ask how you make them? I want to try making my own but not sure where to start. Thank you either way <33

Thank you! You are so sweet :)

I can interpret this question two ways, so I'll answer them both.

*How* do I make them? Using a resin 3D printer (I have an Anycubic Photon Mono 5s) There are multiple types of 3D printers, but for consumers it's generally Resin or FDM (filament - melted plastics). They both have their pros and cons. If you're looking for detail (such as miniatures or figures) you will want resin. However there is a lot more post -processing with the resin printers. With filament you just pull it off the print bed. With resin, I have to give the finished print two baths in alcohol (99%), sanding, curing (You can buy/make 'curing stations,' but you can also cure in the sun which is what I have to do with bigger pieces, it just takes a little longer). After that, I paint. I airbrush where I can and then go in with a brush for finer details. Here is a good overall rundown for resin printing: What Do I Need for Resin Printing? More Than You Think! 2. 3D printers can use a few different types of files, but in general .stl is the one you'll see most. (.obj isn't all that uncommon either) There are a lot of free print files out there. A few of the sites out there are: Thingiverse - All are free CG Trader - Most are paid, a handful of free Cults3D - 70/30 in terms of paid/free. Probably the most affordable. myminifactory.com - Mostly paid, a few free. This is the site to go to for miniatures, particularly for gaming. There are some companies that do nothing but make items for you to print (stlflix comes to mind, but I believe those files are more fitting for an FDM printer). Patreon has a lot of amazing 3D artists who take votes to create monthly figures and if you are subscribed during that month, you'll get all those files. Many of those artists can be found on one of the above mentioned websites as well. Etsy - I'd avoid in general as the vast majority of these files are ripped from actual artists. *However,* there are some legitimate shops on there. In addition, you can find 3D artists on there who will do custom work for you, which brings me to my next point.... The picnic table and chair Toshinori are custom models that I had commissioned because I can't do them myself (I had several made) Blender / Zbrush seem to be a couple of the more common methods for designing - Blender is free, so if you have the patience and time, you can teach yourself. SinceI arranged (and paid ... more than I'm willing to admit) for the custom files, they are mine and that includes the copyright to them. I can do what I want with them -- obviously that doesn't mean I have any sort of copyright over the *character,* just the print file. It would be like buying a commission with the copyright from an artist for a piece of fan art. If you are looking for specific figures, there are a great great many out there, although there are a few I've yet to see made. (Emiya Archer, I'm looking at you!) There are a *ton* of my hero academia models out there - even miniature gaming versions. I've seen Cosplay pieces as well as wall decor, cookie cutters, tons of figures, headphone holders and more. There are a number of All Might / Toshinori figures to be had. 8.8k search results for 3D models to 3D print with the keyword(s) “All Might”・Cults I hope that helps you some. It was a pretty open ended question. Feel free to send a message, I'd be happy to answer more for you.

#ask blog#ask me anything#anon ask#3d printing#all might#my hero academia#toshinori yagi#3d art#anime figure

1 note

·

View note